Plans for an Information Philosophy Institute

Design and Building

We collect all our thoughts in a single document so general contractors can understand the full scope of possible work.

But we divide the work into phases so a single contractor could take full responsibility for a given phase.

Phase 1, Demolition of Boilers-Pipes-Radiators, Ceilings, and Wall,

We decided to do the demolition phase ourselves to get a good look at any problems and found significant damage hiding behind the walls and ceilings.

The basement had a horsehair plaster and lathe ceiling attached to floor joists, then a drop ceiling suspended a few inches below. The plaster had been pierced to install fluorescent lighting up between the joists. Plaster was crumbling and falling down in many places, making the basement dusty and dirty.

Steam pipes were too low for normal headroom. We decided to switch from steam heat to forced hot water.

Electrical wires, thirty Merlin PBX wires, doorbell wiring, and many other wires criss-crossed the cellar, lying on the ceiling tiles and randomly breaking through the plaster, which was constantly disintegrating into dust.

The oldest electrical wires were deteriorating cloth insulated inside ancient BX metal armor.

Low-voltage electronics cables from our webcasting studio to the switcher and green room were very difficult to manage.

We decided to remove the drop ceiling and demolish the plaster and drop ceilings to get a clear look at floor joists and first-floor planking. There was no blocking between the joists, so at many places floorboards were spongy and noisy, pulled loose from the sub-floor.

We removed all of the BX and any obsolete wires, many of which were wrapped over and under pipes and haphazardly stapled to beams and joists with non-insulated staples. We reorganized locations for wires, attaching them neatly with insulated staples. Wires now run only down the long corridor between the main beams, then out between the joists.

This also provides us clear open paths for PEX-A piping over the main load beams and between the joists for a new forced hot water heating system in phase 2.

We removed two inefficient steam boilers and all piping and radiators on the three upper floors.

We can now arrange for an electricity inspection before any later phases that may hide the wiring.

We have finished removing the sheetrock outer walls, studs, etc. which were severely water damaged.

We demolished the existing interior walls that must be moved to new places for the larger bathroom and for the kitchen/workshop wall, which will eliminate a door to workshop. Most studs and the 2"x4" sleeper were badly rotted.

We may also then excavate the bathroom concrete floor to access the sanitary drain, and to lower it to the level of the tile floor.

We removed the old floor tiles in preparation for new continuous flooring. Many places will need to be leveled with new concrete and/or leveling liquid. We may need to remove the uneven concrete floor, dig down several inches and pour a new flat floor, to achieve the required 7'3" (or maybe even 7'6"?) required ceiling height.

We found water and termite damage to the main beams and a dozen joists below the upper-floor bathrooms. Plumbers had cut deeply into the joists to position the bathtub drain and upper floors were sagging below level.

We consulted a structural engineer who said the weak beams and joists should be sistered with new wood, 2" x 10" LVL lumber on either side of the beams through-bolted every 1.5 feet with 1/2" x 10" bolts.

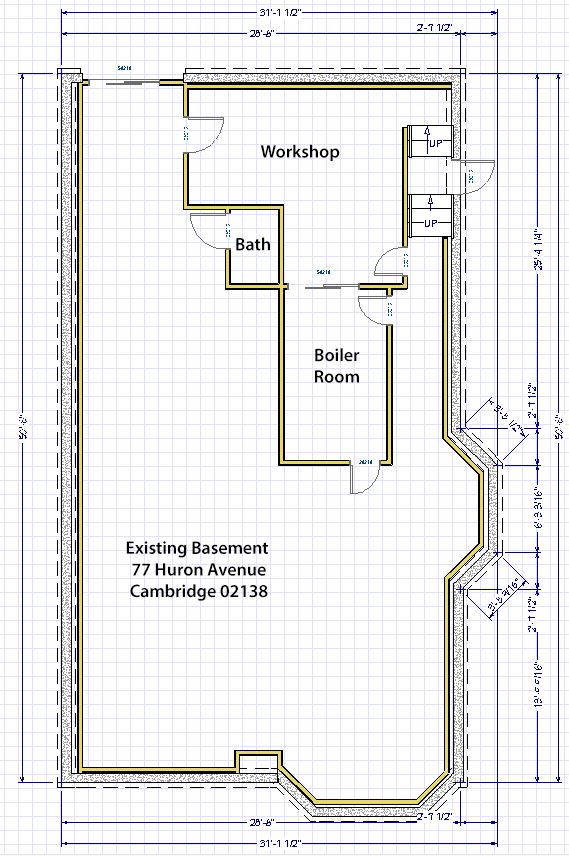

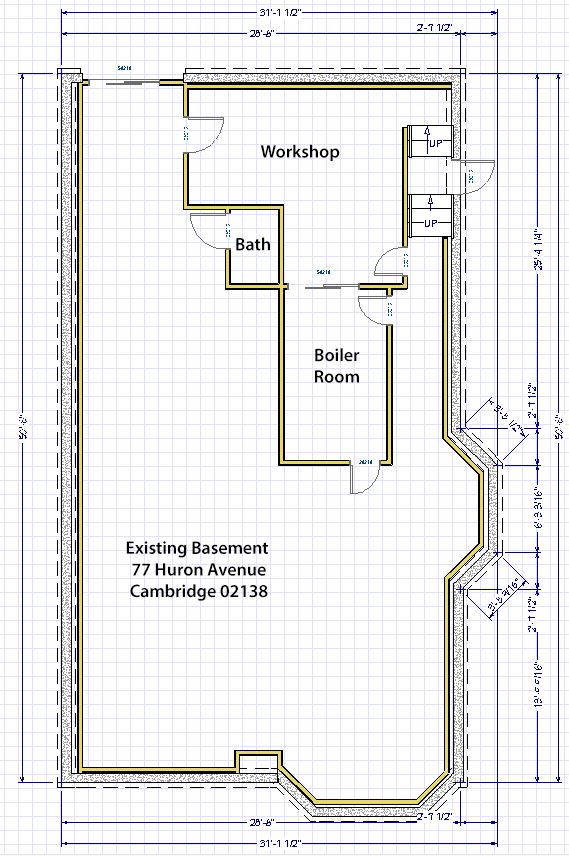

Phase 2, New Heating

A new forced hot water heating system will be installed in about half the space of the old boiler room.

Fire retardant walls and ceiling are needed for the boiler room.

It should have zone control for the three upper floors and for future basement and garage heating.

About 17 new European style, white wall-mounted radiators will be installed on the upper three floors.

Wirsbo/Uponor AquaPEX (PEX-A) piping will mostly follow the existing holes for the old steam radiators. We hope to hide most piping inside partitions.

Replace the hot water heater with an indirect tank with heat exchanger in the boiler.

Manifolds needed

-

5-loop master manifolds (supply and return) in boiler room with programmable flow actuators. (Size? 1 in. input, 3/4 out?)

-

Three 5-loop manifolds (e.g., 3/4 in, 1/2 out?), one for each floor, mounted above corridor between main beams with flow restrictions and home runs to radiators. Front/middle bedrooms, and rear bedroom/bath share a home run. Large front rooms have two. Kitchen has one.

-

Thermostatic valves on all radiators to balance room temperatures beyond flow restrictions?

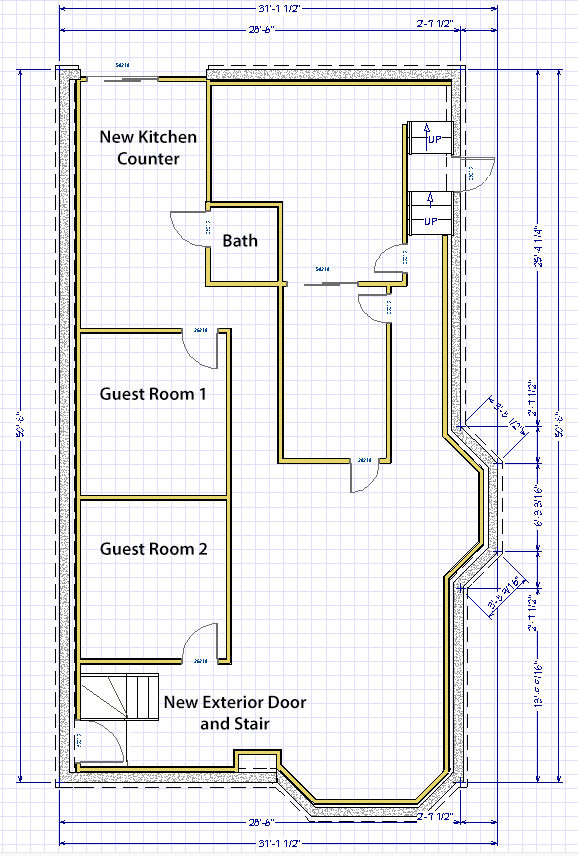

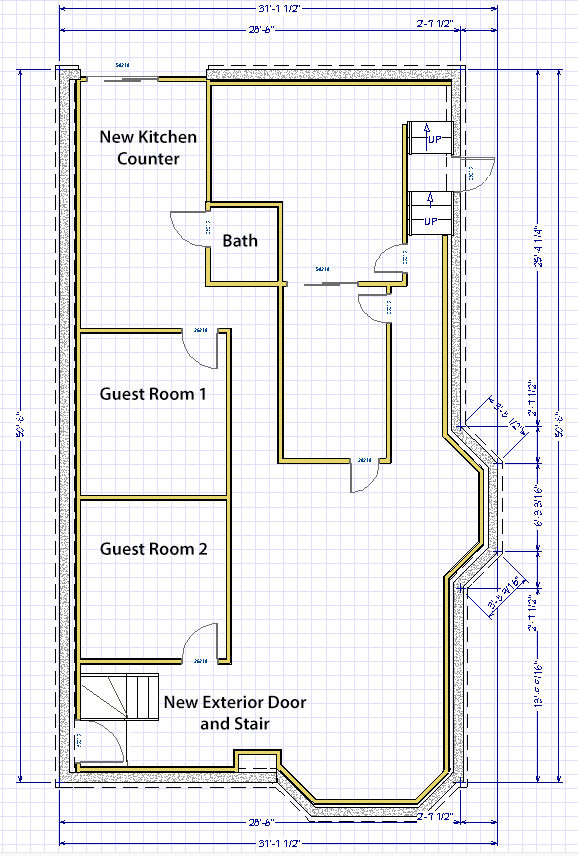

Phase 3, New Front and Renovated Rear Entrances, Renovate Bathroom, Add Kitchenette

- New door and stair at front of the basement, opening on the driveway, to provide another safe egress. Structural engineer is needed to approve framing to support the existing staircase above.

Visualization of new side entrance

Visualization of new side entrance

- Replace 6-foot sliding door at rear with a standard 80" door (probably need to relocate concrete steps). Might we house the new stairs inside the basement, with new exterior walls?

-

Three new casement sliding windows, with screens

-

Renovate the existing half-bath to include a walk-in shower. Enlarge bath from 7' x 3.5' to 7' x 5'.

-

Excavate the current concrete floor in bathroom to access the cast-iron sanitary drain to make appropriate plumbing connections.

-

Move two existing Lally columns approximately two feet to locate them inside the new bathroom walls. This will require new concrete footings for the two columns.

-

Move existing workshop wall back to line up with bathroom, move workshop sink.

-

Add a new kitchen sink and counter for adjoining kitchenette along new kitchen/workshop wall. Space for microwave, convection oven, and small refrigerator.

-

Add a locking door, perhaps at foot of back side stairs.

Phase 3a, Renovate Two Upper Floor Bathrooms

New walk-in showers, replace leaking pipes, add heated floors, on floors 1 and 3.

Add sister joists to strengthen those badly cut for pipe access. Thread new piping through holes in the joists.

Phase 4, New Ceiling, Outer Walls, and Partitions for Two Guest Rooms in Basement

-

On recommendation of a structural engineer, we are sistering weakened beams with 2" x 10" LVL lumber and many joists with 2" x 8" LVL. We then hope to raise some areas back to their original height.

-

We will move two existing Lally columns, preparing standard footings with steel reinforced concrete

-

Once the joists are strong, we will need a new subfloor and hardwood or laminate flooring in the first floor corridor.

-

Blocking/bridging between floor joists as needed to prevent squeaking.

-

R-19 insulation between floor joists for sound isolation.

-

Removable ceiling panels, many with recessed LED lighting fixtures with integrated junction boxes. Three-way switches both downlights and "fluorescent" LED tubes.

-

Upper four feet of exterior walls will have built-in bookshelves with alternating verticals "bookworm" style.

-

Thin rigid insulation or spray foam on cement-block wall behind bookshelves

-

Small air conditioners in guest rooms through the cement blocks? (with minimal projection into driveway)

-

Lower half of exterior walls (rubble foundation) needs masonry repointing with "breathable" lime mortar

-

R-13 insulation behind lower half of exterior walls against the rubble foundation

-

R-13 insulation in partition walls to block sound

-

Electric outlets in partitions

-

Radiator pipes (PEX-A) in partitions

-

Basement floor needs to be leveled. First build partitions and the level rooms separately. Bathroom concrete floor needs to be excavated and lowered to match kitchen/common room.

-

New vinyl sheet flooring in basement, perhaps different designs in different rooms? Laminates are vulnerable to flooding, which we have had in the past. Two sump pumps at the front might eliminate floods? New downspouts at the front and rear of house should be installed.

Visualization of new side entrance

Visualization of new side entrance

Visualization of new side entrance

Visualization of new side entrance